设计

JXPACK 的内部团队精心打造定制塑料瓶、罐和容器——释放形状自由、材料多样性和创新潜力(符合人体工程学的曲线、回收混合物、智能功能)。

JXPACK 最低订购量

100毫升以下

各类液体产品包装瓶的最低订购量为10,000个。

100-150毫升

最低订购量仅为 5,000 件,适用于包装各种不同的液体产品。

超过150毫升

最低订购量为10000件,外观时尚,采用3D模型制作。

JXPACK定制塑料容器选项

塑料瓶

JXPACK拥有20多年定制塑料瓶经验,兼具灵活性和精准性:灵活的模具:快速成型,打造大胆造型(轮廓、不对称)——塑料比玻璃更具成本效益优势。多维定制:注塑颜色、纹理、智能表面(例如二维码)——充分发挥塑料的多功能性。

塑料罐

作为全球定制塑料罐专家,JXPACK 提供轻便、防碎的罐子。我们的团队可根据您的产品需求(例如,化妆品密封罐)定制形状、材料(再生材料混合物、抗紫外线树脂)和瓶盖。

塑料小瓶

凭借数十年的定制塑料小瓶专业经验,JXPACK 充分利用塑料的便携性。我们可根据客户需求定制尺寸、形状、瓶盖和表面处理,并提供材料升级(抗菌、可回收),以满足样品包装等应用场景的需求。

定制塑料容器设计,从概念到商业化

我们的团队将从一开始就与您紧密合作,充分了解您的需求和期望。他们还会提供有益的设计方案和生产建议。我们承接各种规模的订单,最低起订量为100件。

标准库存

预制设计

利用我们3000多个独家库存设计,快速、经济高效地将产品推向市场。浏览我们的产品目录,或告诉我们您的独特需求。

创建你自己的

免费设计支持

对于大批量订单,我们提供免费指导,为您量身定制专属容器。我们负责五步流程:设计咨询 + 技术可行性检查。

为什么选择定制塑料瓶设计

当您的品牌需要脱颖而出时,定制塑料瓶可助您实现设计自由和经济高效的创新。您可以定制瓶身形状、颜色、瓶盖,甚至触感纹理或智能表面,使其与您的产品和品牌形象完美契合。

创意优势:大胆的造型(不对称、符合人体工程学的曲线)、智能集成(支持二维码的表面)、触感饰面(柔软触感涂层)。

装饰创新:模内贴标、注塑成型色调、哑光/亮光效果——无需二次贴标。

生产灵活性:快速调整模具,适用于小批量试验,最低起订量低(与玻璃的刚性模具相比)。

质量控制:防变形设计,耐紫外线树脂,适用于户外环境。

可持续性杠杆:再生混合物,单一材料结构,便于回收利用。

一步一步制作你的专属塑料瓶

#1 确定你的塑料瓶创意

无论我们是根据草图、其他容器的样品,还是仅仅讨论您的想法,我们的团队都会与您紧密合作,深入了解您的具体需求。我们将帮助您探索各项要求,提出符合您最初设想的方案,并考虑价格和制造方案等因素,以改进生产和灌装流程。

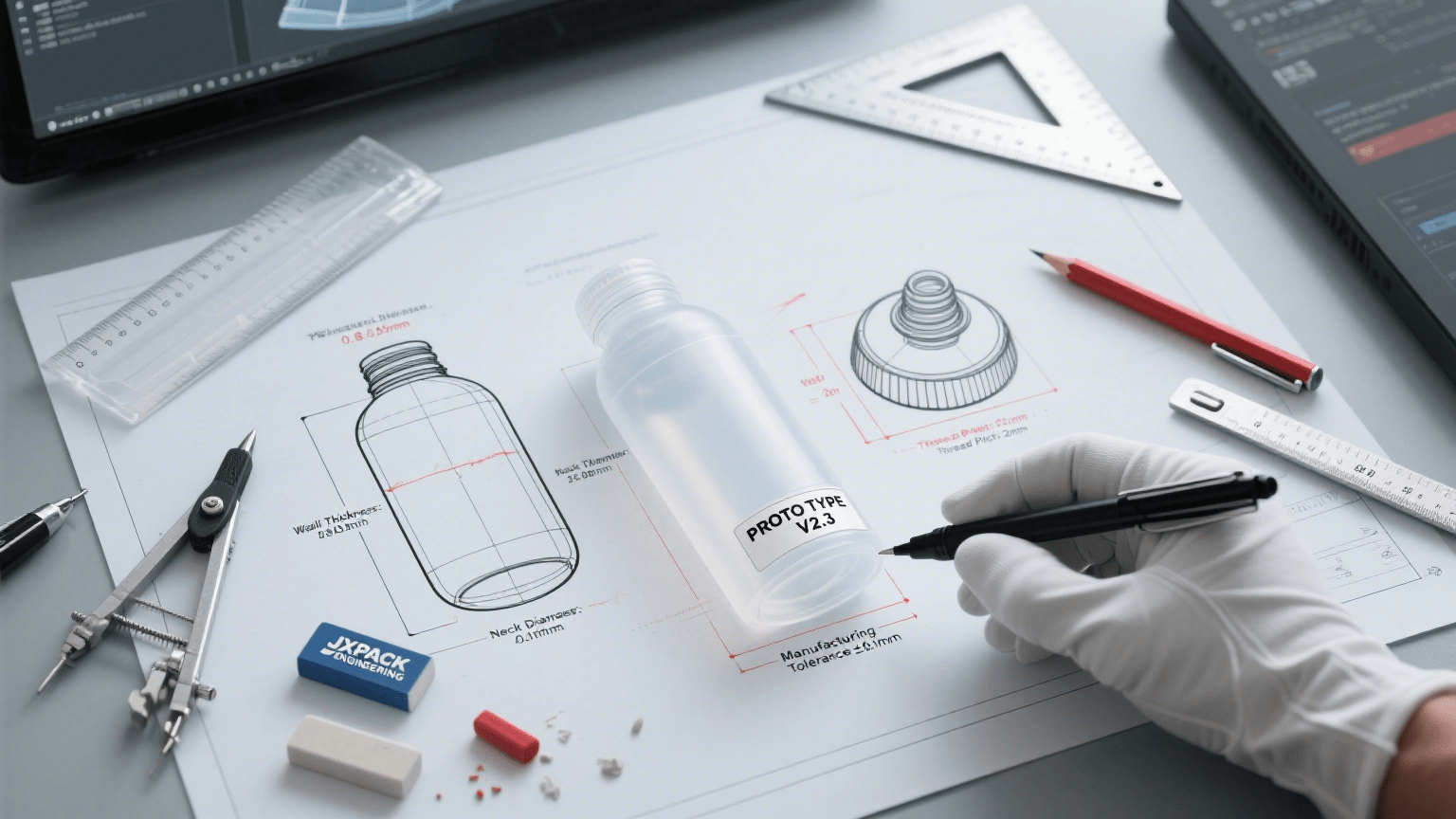

#2 定制塑料瓶蓝图

设计定稿后,我们会制定一份精确的蓝图,明确可测量的尺寸(例如壁厚、颈部直径),确保符合塑料的制造公差。在这个阶段,我们会对规格进行严格的验证,然后再进行生产。

我们的跨学科团队(设计师 + 工程师)提供以下支持:

- 瓶身及瓶盖设计

- 分配/计量系统

- 人体工程学 + 外形优化

- 快速原型制作

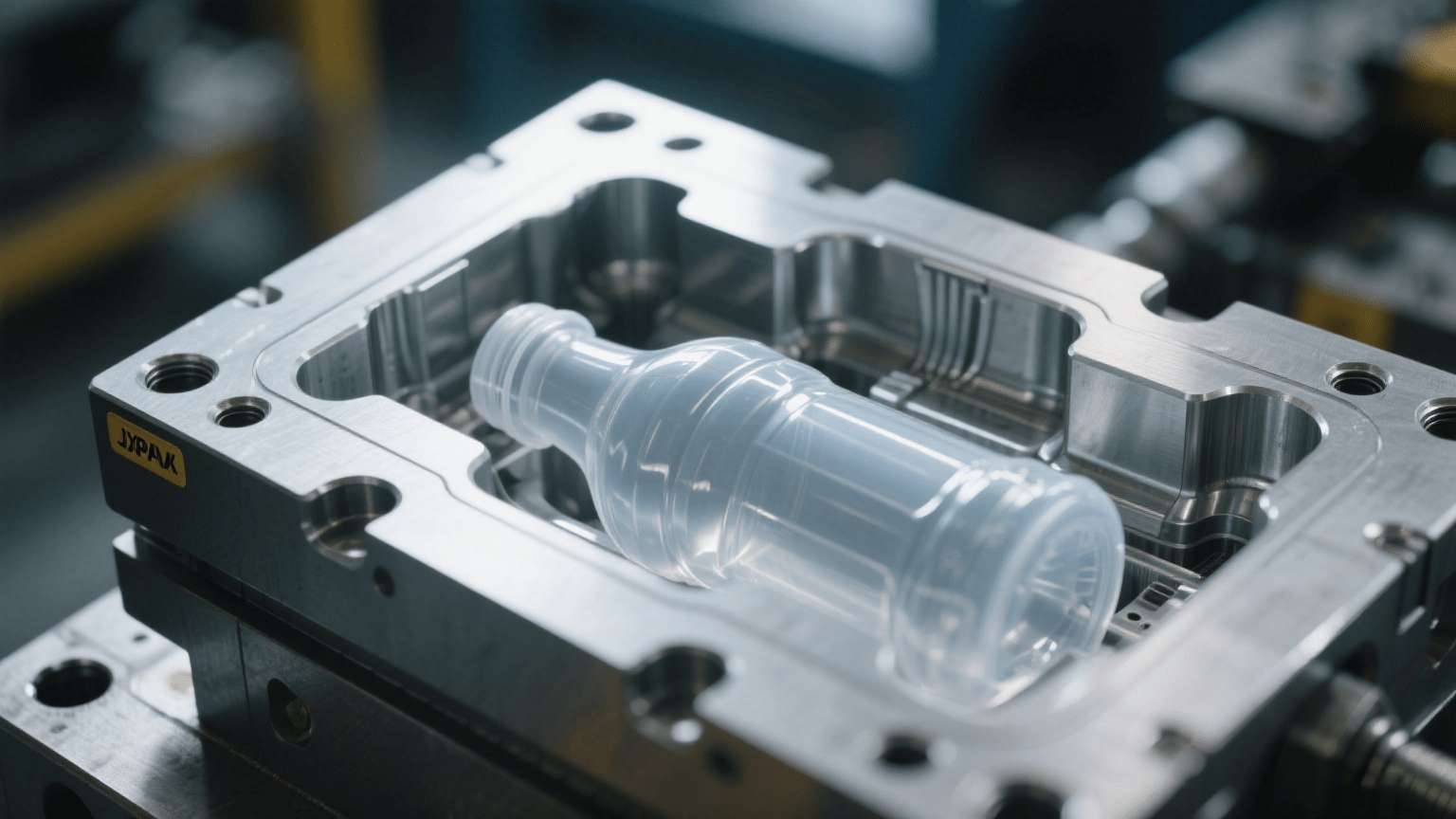

#3 定制塑料瓶的敏捷工具

塑料模具以无与伦比的灵活性将概念变为现实——JXPACK 提供快速原型模具(适用于小批量试验)和批量生产模具,所有模具均可根据您瓶子的独特几何形状量身定制。快速调整和低成本迭代确保从概念到成品上架的无缝衔接。

#4 快速取样用于定制塑料瓶

一旦收到试模并确定生产档期,我们会迅速制作塑料瓶样品,验证其设计、功能和尺寸是否合适。利用低成本的模具调整,在批量生产前进行迭代改进。

#5 可扩展的塑料瓶生产与包装

我们选用优质树脂(再生混合树脂、食品级聚合物),并在较低温度下熔化(玻璃熔化温度为 1200°C)。通过注塑吹塑或挤出吹塑成型,我们将瓶子塑造成各种形状:

- 短颈

- 苗条

- 长颈

- 圆润

- 纽扣状

- 加冕

成型后,我们会检查瓶壁厚度、接缝完整性和抗紫外线性能。然后,我们会使用可回收材料包装瓶子,以实现高效、可持续的运输。

专业定制塑料瓶制造商

定制塑料瓶的生产需要创新、灵活和智能工具。与一家兼具专业技术、可扩展基础设施和材料多样性的制造商合作至关重要。

JXPACK在塑料包装领域拥有超过15年的经验,这使我们具备了竞争优势:

敏捷生产:模块化生产线(8 个以上装置)可适应小批量试验或大批量订单,利用注塑/挤出成型实现精度。

材料掌控:从再生PET到智能树脂,我们满足各种需求(例如,可挤压的PE,防碎PP)。

成本与速度:精益工具 + 快速迭代缩短了产品上市时间,并以具有竞争力的价格提供优质、可持续的解决方案。

我们提供从设计到交付的无缝服务。JXPACK 团队随时准备将您的愿景变为现实。